- WISE

- ARO/ Ingersoll Rand

- ROSEMOUNT

- BÌNH KHÍ HIỆU CHUẨN

- LUOYANG

- CABLE SOURCE

- DRAGER

- J & R TECHNOLOGY

- HUNAN

- YOKOGAWA

- SHINKAWA

- UNILOK

- WOORI

- SENTEC

- DOW VALVE

- ROTAREX

- YAMARI

- HORIBA

- KSK

- ASTTAR

- KANOMAX

ĐỒNG HỒ CHÊNH ÁP P670 ( SERIES P671, P672, P673 ) WISE

Vật liệu: Inox 304 / 316, Monel và Hastelloy-C

Đường kính mặt: 100 và 160 mm

-

1955

-

Liên hệ

-

- +

- Tổng quan

- Thông số kỹ thuật

- Bình luận

1. Giới thiệu đồng hồ chênh áp P670

Đồng hồ chênh áp P670 được thiết kế với cấu trúc có thể bảo vệ ống Bellows chống lại áp suất quá cao, và có thể được sử dụng cho đo áp suất chênh lệch của bộ lọc, đồng hồ đo lưu lượng, v.v. bằng cách sử dụng lỗ hoặc để đo mực nước của bể chứa. Series P671 – P672 – P673 thuộc dòng Đồng hồ áp suất Wise, với ống Bellows bằng thép không gỉ được gắn trên một bộ cân bằng lực cho phép đọc trực tiếp áp suất chênh lệch thực tế.

Sản phẩm được phân phối duy nhất tại Wise Việt nam.

2. Các thông số kỹ thuật

✦ Đường kính mặt – Đường kính danh nghĩa :

- 100 and 160 mm

✦ Đơn vị đo :

- MPa, kPa, bar, mbar

✦ Dải đo :

- Series P671 : 0 ~ 4 kPa, 6 kPa, 10 kPa

- Series P672 : 0 ~ 25 kPa to 0 ~ 0.25 MPa

- SeriesP673 : 0 ~ 0.4 MPa to 0 ~ 2.0 MPa

✦ Áp suất tĩnh :

- P671 : Max 4 MPa

- P672 and P673 : Max.10 MPa

✦ Nhiệt độ làm việc :

- Môi trường: – 20 ~ 65oC

- Chất lỏng: max 100oC

✦ Hiệu ứng nhiệt độ :

Độ chính xác ở nhiệt độ trên và dưới nhiệt độ chuẩn ( 20oC ) sẽ được ảnh hưởng trong khoảng ± 0,5% trên 10oC toàn thang đo.

✦ Cấp chính xác :

- ±1.0 % of full scale

- ±1.6 % of full scale

✦ Degree of protection

- EN60529 / IEC529 / IP55

3. Vật liệu và tiêu chuẩn kết nối

| Bộ phận kết nối áp suất |

|

| Ống Bellows |

|

| Vỏ | Thép không gỉ (304SS) |

| Dầu | Dầu silicone |

| Kính quan sát | Safety glass |

| Số trên mặt đồng hồ | Nhôm trắng sơn đen |

| Kim đồng hồ | Hợp kim nhôm đen |

| Tiêu chuẩn kết nối với hệ thống |

|

| Bộ phận phụ trợ | Mounting bracket for 2″ pipe mounting with silver gray finished steel |

| Tuỳ chọn |

|

4. Cách lắp đặt và vận hành đồng hồ chênh áp P670

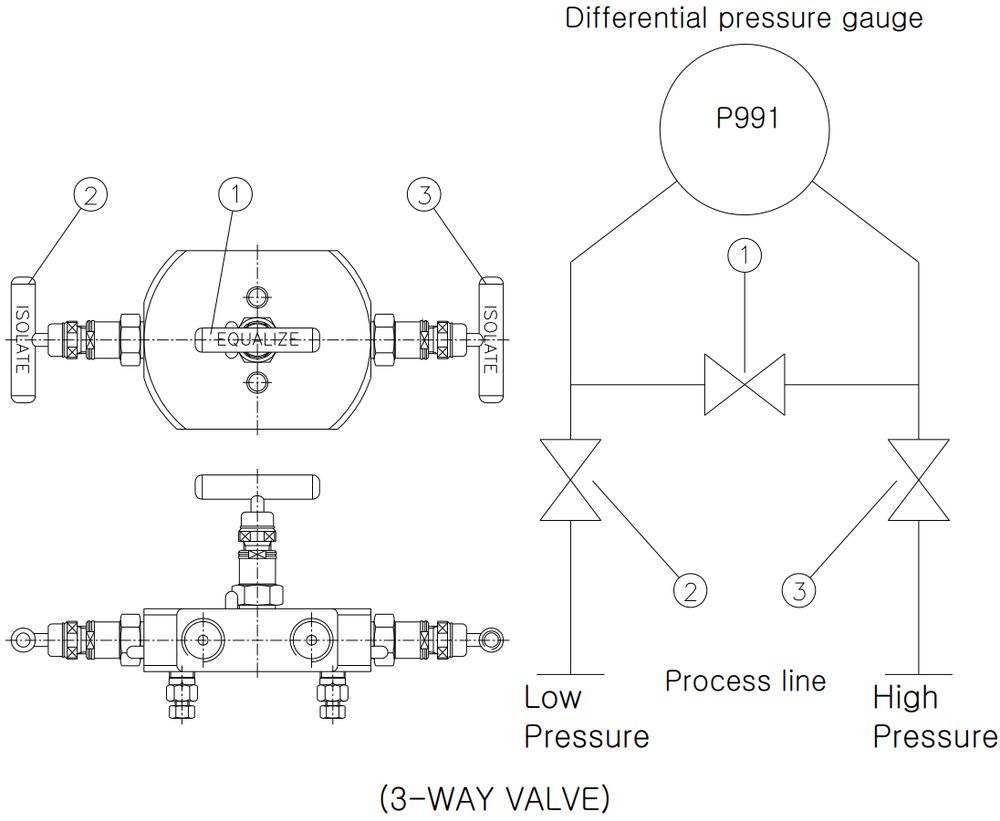

Đối với 3-way manifold valve

① Van cân bằng.

② Van áp suất thấp ( LP Valve ).

③ Van áp suất cao ( HP Valve ).

- Đầu tiên khi cài đặt đồng hồ đo áp suất Wise, cần đóng tất cả các van lại.

- Sau khi cài đặt xong, trước tiên hãy mở van ① , sau đó mở van ③ kiểm tra xem con trỏ có chỉ về “0” hay không, nếu có lỗi thì điều chỉnh Zero point adjustment.

- Trước khi vận hành, hãy đảm bảo rằng tất cả không khí thoát ra khỏi đồng hồ đo bằng cách mở lỗ thoát khí ở phía trên cùng đồng hồ. Không khí còn sót lại có thể gây ra lỗi đo áp suất.

- Sau đó, mở van ② rồi đóng van ①. Sau đó đảm bảo rằng đồng hồ đã chỉ ra phần áp suất chênh được chính xác.

5. Lưu ý khi sử dụng đồng hồ

Khi sử dụng Đồng hồ chênh áp Wise P670 ( series P671 – P672 ) chúng ta cần lưu ý một số điều sau:

- Để ngăn ngừa hư hỏng của bộ phận đo vi sai, hãy vận hành đồng hồ đo cùng với 3-way and 5-way manifold valve và kiểm tra đầu vào của dòng áp suất cao – thấp trước khi lắp đặt.

- Bộ phận đo chênh lệch áp suất phải được lắp đặt ở vị trí cao hơn so với bộ phận khuếch tán áp suất trong quá trình đo áp suất chất khi và thấp ơn trong quá trình đo chênh lệch áp suất chất lỏng.

- Với hệ thống có chất lỏng ăn mòn, bạn phải chọn màng ngăn chống ăn mòn hoặc side diaphragm.

- Trong trường hợp bạn chọn side diaphragm thì high side và low side không được lắp đặt vào cùng một lúc.

- Zero point adjustment được điều chỉnh bằng cách vặn vít bên trong đồng hồ, khi đó người sử dụng cần tháo nắp dầu trên đỉnh đồng hồ để có thể điều chỉnh.

- Trong trường hợp hoạt động trong chất lỏng có nhiệt độ cao, sử dụng seal pot để giữ chất lỏng đi vào của máy đo ở nhiệt độ cho phép.